In the manufacturing sector, achieving operational efficiency and maintaining high product quality are crucial priorities. Leading manufacturers are increasingly turning to data and machine learning (ML) to stay competitive. For AdvanSix, a $1.5B leader in chemical manufacturing, data and ML have become critical drivers of innovation. Partnering with Lovelytics and leveraging the Databricks Data Intelligence Platform, AdvanSix successfully demonstrated the transformative potential of predictive analytics, setting the stage for widespread adoption across their operations.

Harnessing Data and ML for Real-Time Manufacturing Insights

AdvanSix identified an opportunity to improve their chemical development process. This process involves precise chemical reactions that demand tight control of temperature, pressure, and material composition to ensure high-quality output. The company faced growing operational complexity and recognized that by modernizing their data infrastructure and improving their ML Operations (MLOps) and ML models, they could improve product quality at scale and significantly enhance product consistency while driving down losses due to quality issues.

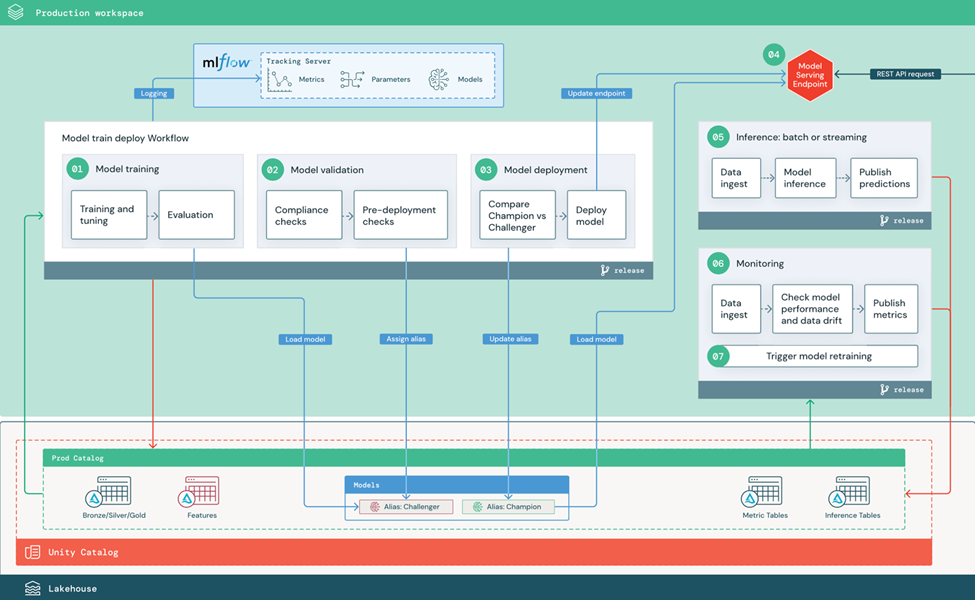

The existing ML models provided a starting point for increased accuracy, scalability, and efficiency. By implementing MLOps, optimizing data pipelines, and unlocking the power of real-time data processing, AdvanSix could drive greater operational efficiency and product consistency. Seizing this opportunity, AdvanSix and Lovelytics built a scalable foundation for predictive analytics across their manufacturing process. In partnership, they developed a proof of concept (POC) for a modern ML solution on Databricks, leveraging Delta Lake and advanced data pipelines to revolutionize their manufacturing processes.

The Solution: A Seamless Integration of Data Pipelines and ML with Databricks

Adding on to the POC, Lovelytics collaborated with AdvanSix to design and implement a modern, production-ready ML environment tailored to their needs. The project centered on building robust data pipelines, refining an ad-hoc ML model, and operationalizing it within the Databricks platform. The design allowed AdvanSix to monitor, analyze, and predict outcomes at every stage of the acid development process, from initial material mixing to final quality assurance.

The project was broken into key phases:

- Laying the Groundwork for Scalable Machine Learning Success

- Lovelytics established a scalable architecture on Databricks, integrating data pipelines for seamless data flow. This setup provided the groundwork for ML experimentation and facilitated rapid scaling to future production use cases, such as optimizing reaction times, reducing material waste, and predicting equipment maintenance needs, ultimately driving enhanced operational efficiency and improved product consistency across the manufacturing lifecycle.

- Enhancing Machine Learning for Continuous Improvement and Scalable Efficiency

- The existing ML model was refactored to align with Databricks’ architecture, making it modular and reusable. Lovelytics implemented periodic batch training and retraining processes to ensure continuous improvement and model accuracy, empowering real-time insights into FAV and ensuring that chemical reactions remained within desired tolerances for maximum yield.

- Equipping AdvanSix for Scalable Innovation and Lasting Success

- Knowledge transfer was a priority throughout the engagement. Lovelytics collaborated closely with AdvanSix’s data scientists, ensuring they could independently manage and scale the solution. This enabled the internal team to confidently adapt the solution to evolving production needs, such as fine-tuning manufacturing parameters or implementing new predictive analytics use cases. Additionally, governance and administration best practices were embedded into the system, ensuring data accuracy, security, and compliance. These practices created a sustainable production-ready tenant that supports innovation across the manufacturing process, enabling AdvanSix to streamline operations, improve product quality, and remain competitive in a rapidly advancing industry.

The Results: Driving Business Value Through Scalable Machine Learning

With the implementation of Databricks and the expertise of Lovelytics, AdvanSix successfully modernized their data infrastructure and optimized their ML operating model. This resulted in:

- Improved Efficiency: Real-time insights into FAV allows AdvanSix to make faster, data-driven decisions, reducing production losses and ensuring consistent product quality.

- Scalable Infrastructure: The new architecture provides a repeatable framework for future ML use cases, accelerating time-to-value.

- Empowered Teams: Through hands-on collaboration, Lovelytics enabled AdvanSix’s internal data scientists to leverage Databricks independently, fostering a culture of innovation.

Additionally, the POC demonstrated the potential for predictive maintenance, paving the way for broader adoption of ML models across AdvanSix’s manufacturing processes.

What’s Next: Scaling Innovation Across the Manufacturing Process

With the success of the POC, AdvanSix plans to expand its use of Databricks and ML across other production processes, unlocking new efficiencies in the intricate workflows of chemical manufacturing. Advanced analytics and AI will enable the company to develop models with greater precision, predict potential disruptions, and dynamically adjust operating conditions to maintain optimal output. This data-driven approach reduces waste, minimizes energy consumption, and ensures product consistency, all while meeting stringent industry standards. The foundation laid by Lovelytics has created a scalable blueprint for innovation, positioning AdvanSix to leverage advanced analytics and AI to maintain its competitive edge in the chemical manufacturing industry.

Ready to Transform Your Manufacturing Process with Data and AI?

Discover how manufacturing organizations have revolutionized their operations with ML and data-driven insights. Partner with Lovelytics and Databricks to modernize your data infrastructure, enhance efficiency, and unlock scalable innovation.